Our main goal is to design and produce plastic tunnel forms used in various construction projects

Home / Products

Plastic panels (molds) for casting and forming concrete as an alternative to plywood

Polypropylene Product

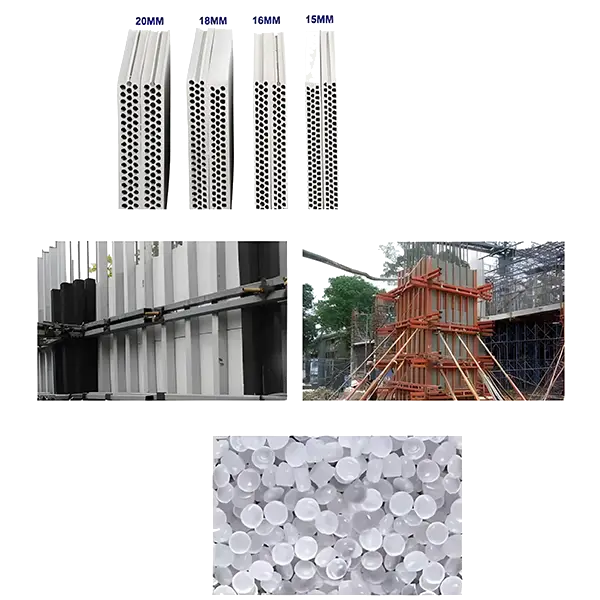

Hollow plastic sheets (PP) made of polypropylene with a thickness ranging from 15 to 17 mm, and standard dimensions of 1830 mm × 918 mm, weighing 13.5 kg per sheet. Production capacity reaches 500 kg per hour or 1600 to 2000 square meters per day (24 hours).

Raw Materials :

Plastic Panels :

– Material : Polypropylene

– Melting Point : Up to 167°C

– Softening Temperature : Up to 150°C

Properties : High heat and corrosion resistance, strong impact resistance, enhanced with increased ethylene content

Surface Hardness : Excellent scratch resistance

Composition : 95% polypropylene with a unique formulation meeting international construction standards

Usable Temperature Range for Molds : 20 to 90°C

Customization : Raw materials can be tailored according to project design and requirements

Advantages

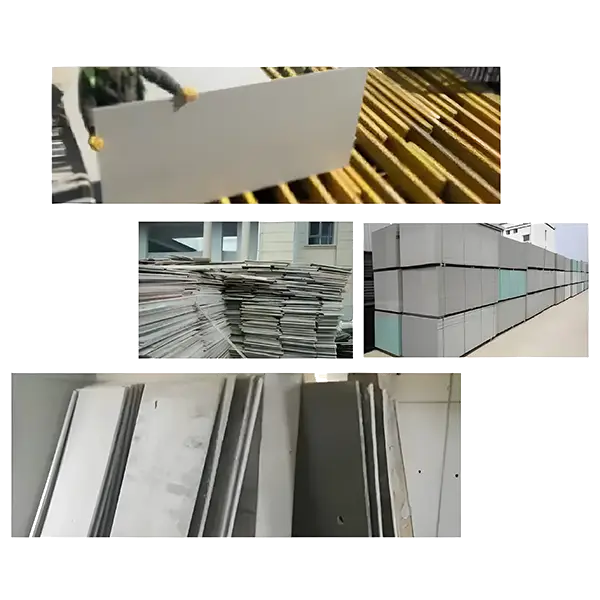

Reusability

Plastic panels can be used 60 to 100 times. The molds are tested to ensure at least 60 cycles of repeated use for concrete casting

100% Waterproof

The hollow plastic molds are weather-resistant, ensuring that rain or rust does not affect the quality of the molds.

No Need for Release Oil

The surface is designed with additives that allow the panel to withstand acidic or alkaline environments. There is no need for oil to remove or separate the molds, making the dismantling process very easy.

High Usability

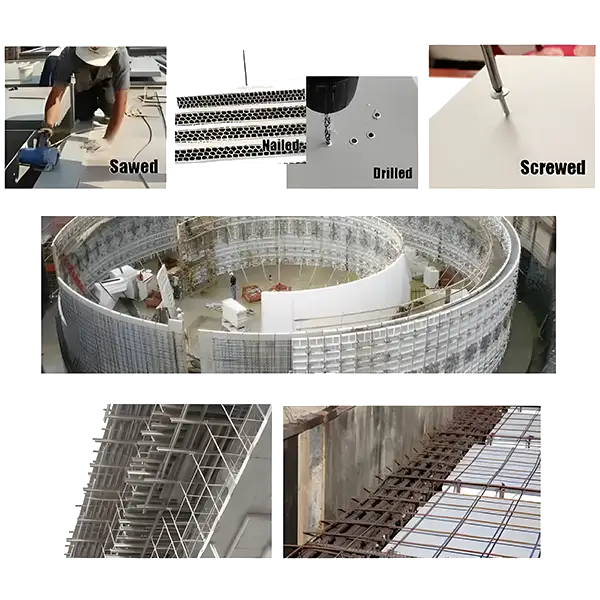

Easy to use and compatible with tools like saws, nails, drills, and in cutting operations. They are also compatible with other materials like wood, steel, and aluminum.

Lightweight

Lighter and easier to carry, reducing labor strain and lowering labor costs by 20% compared to plywood.

Easy Maintenance

Plastic components and molten adhesives can repair holes and scratches.

Cost-Effective

One set of plastic frames and molds can complete the construction of an entire high-rise building with 35 floors. They save 60% of the overall budget compared to plywood and metal molds.

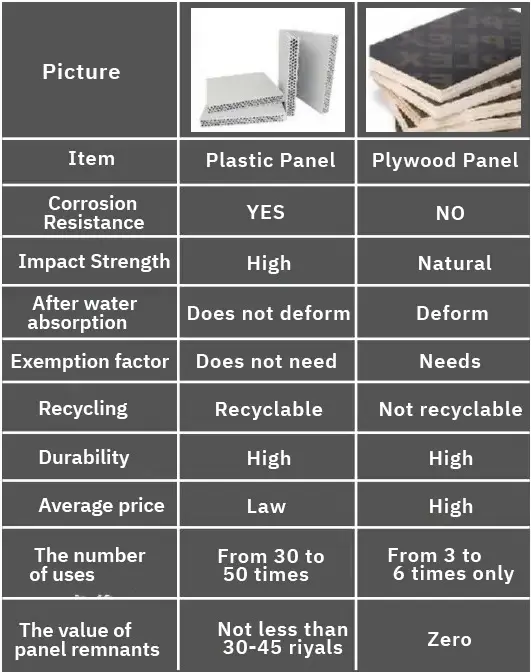

Comparison between Plastic Concrete Panels and Wooden (Plywood) Panels

Advantages of Round Drilling Structures

Triangular Layout : Forms a stable, more durable, and stronger structure

Cross Layout : Increases contact area with nails, enhancing friction and cohesion

Tree-like Structure : Distributes surface load capacity, leading to greater load-bearing capacity and a stronger surface with less damage.

Reduced Thermal Expansion and Contraction : Helps maintain structural stability under the influence of temperature changes.

Installation and Fixing Instructions - Sample Size: X2440X181220 mm

Stage 1 : Slap

The spacing between supports depends on the thickness of the concrete slab. Generally, if the slab thickness is 200 mm, the spacing between supports should be 300 mm to 400 mm

Stage 2 : Wall

The spacing of the supports is adjusted according to the height and thickness of the wall. For example, for a wall with a height of 2800 mm and a thickness of 300 mm, the support spacing should be 200 to 250 mm. If the wall width exceeds one meter, the fixed frame must be reinforced

Stage 3 : columns

There should be no gaps in the connection between the shear wall pouring and the column pouring. The negatively angled part (bottom of the wall) must be supported with an appropriate column, wall, and pouring connection. The supporting molds for the wall and column can be assembled into one block and installed, then the slab is placed. This reduces labor intensity and improves the mold effect

Stage 4 : Nails

When driving a nail into the molds, the distance from the edge of the molds should be 15 to 30 mm. The appropriate nail length is generally 40 to 50 mm

Usage Areas :

In Casting Work :

The product can be used in various sectors, especially in casting work. The surface performance remains at its highest levels even when the panels are reused multiple times, depending on site conditions. It is recommended to use a platform system for floors with concrete thicknesses up to 25 cm with spacings ranging from 25 to 30 cm.

In Construction Work :

Used in concrete molds, scaffold platforms, roofing work, and in the manufacturing of floors and parquet.

In the Transport and Shipping Sector :

– Used in trailer floors and side covers, container floors, and the floors and side parts of vehicles, as well as in buses and shipbuilding, especially in the cargo storage areas of the ship.

Other Usage Areas :

Used in children’s toys and musical instruments. It is also used in traffic signals, urban furniture manufacturing, and theater construction. Additionally, it is used in kitchen countertops, textile machine tables, and their cutting benches.

Additional Features

Cost and Time Efficiency: The ease of installation and lifting can reduce the cost and time of your project. The panels weigh 10.25 kg per square meter for 18 mm thick panels and 12.5 kg per square meter for 21 mm thick panels. In addition to their numerous advantages, their applications and functions are like plywood. When used together, they provide a perfect combination.

Distinctive Properties

1.Appropriate Thickness Panels : The panels with standard sizes of 1220 × 2440 mm or 1250 × 2500 mm have a thickness of approximately 18 or 21 mm.

2.High Efficiency and Usability :

– Provides maximum efficiency when used with poured concrete.

– Can also be used with plywood panels and other materials.

3.Distinctive Raw Material :

Based on a raw material manufactured from high-quality nano-technology (polypropylene) at 100% concentration.

4.Shock Resistant :

Characterized by the highest level of shock resistance, to the extent that it remains unbroken even when dropped from a very high altitude.

5.Rust Resistant :

It remains unaffected by pressure or shocks and does not rust due to weather conditions or other factors, unlike plywood and other products.

6.Smooth and Easy Removal :

It does not adhere to the concrete, providing a smooth concrete surface due to the lack of adhesion with the panel surface, which also facilitates its removal after use.

7.Used with Screws :

It can be used for screwing and drilling holes, or it can be used in cutting operations. Additionally, it is easy to assemble and can be easily cleaned with water.

8.Suitable for All Climates :

Delivers optimal performance within a temperature range of -10 to +70 degrees Celsius.

9.Used in Circular Shapes :

Can be used for columns as well as flat walls and floors. It is also very suitable for forming circular walls as it regains its shape.

10.Long Lifespan :

Has a longer lifespan than all grades of plywood, even the most premium ones. It endures longer even under the harshest working conditions.

11.Recyclability :

– The recycling process for these products depends on the weight of the panels, ensuring that even the smallest part of the panels is not wasted during recycling.

-It Can be stored in any environment and is not affected by adverse conditions such as humidity, water, insects, and others.

12.Easy to store :

It can be stored in any environment and is not affected by unfavorable foreign conditions such as humidity, the presence of water, insects, etc.

13.Value Beyond Lifespan :

The panels retain value even after their lifespan has ended, with remnants selling for at least 30-45 riyals per panel, whereas plywood remnants have no value.

Polypropylene Product with Aluminum Frame

Manufacture of Supporting Molds with Automated System.

Specifications of the Produced Workpiece:

-Length: 1000, 1100, 1200, 2400, 2500, 2600, 2700 mm

– Width: 200, 300, 350, 400, 600 mm

– Height: 65 mm

Columns

Main Function : Our concrete casting molds are designed to provide a formwork system suitable for all types of columns, such as rectangular, L-shaped, decorative, and round columns. Our design team can customize the columns according to customer requirements.

Foundation Wall

Main Function : Regardless of the size of the foundation wall or whether it is required for a large building or a small villa, our concrete casting panels can be used to meet the customer’s requirements.

Stairs

Main Function : Stairs are a special type of formwork designed according to customer requirements. The molds ensure durability, reliability, and the rapid deployment of stairs in multi-story buildings or large communities.

About us

EMAAR Industrial Building Solutions was established in 2023 in alkharag city, Our main scope is mainly focused on producing PVC frameworks which are usually used in construction projects

office

Copyright 2024 © Emaar Industrial Building